Jacksonlea Buffs Polishing Compounds Store

Transforming raw metal into a mirror-like masterpiece requires the precision and power found in JacksonLea’s industry-leading buffing and polishing compounds. Trusted by automotive experts and master jewelers alike, these professional-grade bars deliver everything from aggressive cutting to a high-luster glow. Every compound, from the classic White SS51 for stainless steel to the deep-coloring C-3 Green Rouge, is engineered for maximum efficiency and a flawless finish. While you won’t find a standalone brick-and-mortar shop, JacksonLea’s legacy of excellence is readily available through elite industrial distributors like Osborn, ISR Industrial, and Steiner Electric.

Top Jacksonlea Buffs Polishing Compounds

JacksonLea SS51 White Standard Bar

This versatile white compound is specifically formulated for high-quality coloring and polishing on steel, stainless steel, and brass, providing a brilliant final shine with its medium-grease consistency.

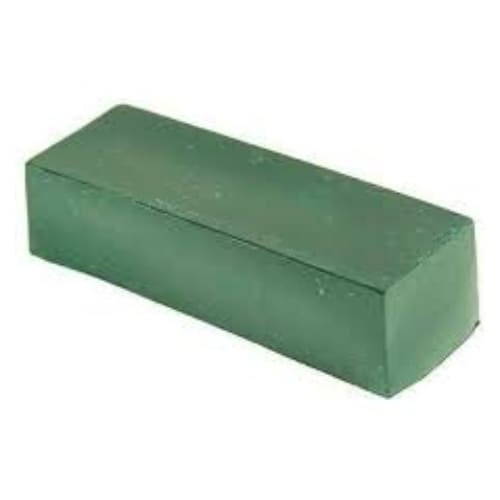

JacksonLea C-3 Green Grande Bar

Widely recognized as a top choice for finishing aluminum and stainless steel, this chrome-oxide based green rouge produces an exceptional mirror finish and rich depth of color on non-ferrous surfaces.

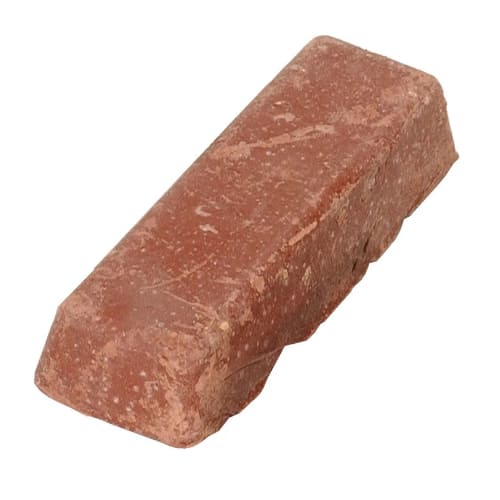

JacksonLea D-14 Tripoli Brown Bar

An essential tool for the initial stages of finishing, the D-14 Tripoli serves as a powerful “cut and color” compound that efficiently removes light scratches from softer metals like copper, brass, and aluminum.

JacksonLea delivers the professional edge required to turn dull industrial surfaces into brilliant, mirror-finished masterpieces.

Professional Finishing Solutions

JacksonLea offers a comprehensive suite of surface treatment tools designed for precision, durability, and unmatched shine across various metal substrates.

Solid Buffing and Polishing Compounds

These premium bar compositions are engineered in various grades to provide everything from heavy-duty metal cutting to the final, high-luster coloring required for exhibition-quality finishes.

Buffing Wheels and Buffs

Featuring high-performance airway, sisal, and fabric designs, these buffs are built to hold compounds effectively while standing up to the rigorous heat and pressure of industrial machinery.

Specialty Polishing Products and Cleaners

This category focuses on the essential post-polishing phase, offering specialized solutions that remove residue and ensure the finished metal remains pristine and free of contaminants.

Industry Expert Testimonials

Marcus Thorne “After twenty years in custom automotive restoration, I’ve found that the JacksonLea SS51 White compound is the only product that consistently brings out a true deep-mirror finish on stainless trim without leaving greasy streaks behind. I recently paired it with their sisal buffs for a heavy-duty restoration on a vintage truck grille, and the way it cut through decades of oxidation while staying cool on the wheel saved me hours of labor. It’s rare to find a brand that balances aggressive cutting power with such a refined final polish in a single product line.”

Elena Rodriguez “As a production manager for a high-volume jewelry manufacturing firm, I rely on the C-3 Green Rouge for our final finishing stage because its consistency is unmatched from batch to batch. We transitioned to using JacksonLea compounds across our entire floor because they don’t crumble under high RPMs, which significantly reduces our material waste and keeps our workstations cleaner. The precision we get on intricate brass and copper pieces has noticeably improved our quality control pass rate, making these compounds an essential part of our daily operations.”

David Henderson “I’ve experimented with various industrial abrasives for my metal sculpture studio, but the JacksonLea/Osborn airway buffs are in a league of their own when it comes to longevity and airflow. I recently used their Tripoli compound on a large-scale bronze installation, and the compound adhered beautifully to the wheel, providing a steady, even cut that didn’t overheat the metal surface. It’s clear these products are designed for professionals who need reliable results; the finish is always uniform, which is critical when you’re working on pieces that will be under harsh gallery lighting.”

Jacksonlea FAQ

Which JacksonLea compound is best for achieving a mirror finish on stainless steel?

For a true high-luster or “mirror” finish on stainless steel, the SS51 White Buffing Compound is the industry standard for final coloring and polishing. If you require an even deeper, darker color after using the white compound, many professionals follow up with the C-3 Green Rouge to eliminate any remaining micro-scratches and enhance the reflectivity.

How do I distinguish between “cutting” and “coloring” compounds?

Cutting compounds, such as the A-16 Black or D-14 Tripoli, are more abrasive and designed to remove scratches and “level” the metal surface. Coloring compounds, like the SS51 White or Red Rouge, have finer abrasives that refine the surface to produce a high-gloss, reflective shine; essentially, “cutting” prepares the surface while “coloring” provides the beauty.

Can these compounds be used for hand-polishing or are they machine-only?

JacksonLea compounds are designed as solid bars that are meant to be applied to a rotating buffing wheel, as the friction and heat generated by the machine are necessary to melt the binder and transfer the abrasive to the buff. While you can technically rub the bar onto a cloth for manual polishing, the results will be significantly less effective than using a bench grinder or a handheld rotary tool.

Why can’t I find a dedicated JacksonLea retail website to buy from directly?

JacksonLea operates as a specialized brand under Osborn LLC and focuses on industrial-scale manufacturing rather than direct-to-consumer retail. Because they sell in bulk cases to professionals, their products are exclusively distributed through industrial supply chains like Fastenal, ISR Industrial, and Steiner Electric, where you can purchase individual bars or full cases.

What is the best way to clean compound residue off a part after polishing?

Once the buffing process is complete, any waxy residue left behind can be removed using JacksonLea’s specialized specialty cleaners or a simple mixture of warm water and a degreasing detergent. For precision parts, many shops use an ultrasonic cleaner or a wipe-down with mineral spirits to ensure the metal is perfectly clean before plating or clear-coating.